Zirconia ceramic is a kind of inorganic non-metallic material with high temperature resistance, corrosion resistance, wear resistance and excellent conductivity.

Product Introduction

Advanced Technical Ceramic Plunger Pump / Dispensing Valves Made From Zirconia

The ceramic plunger pump, a staple in the drilling equipment industry, is renowned for its high-rated pressure, compact design, and efficiency. Its ability to regulate flow makes it an indispensable tool in various high-pressure applications such as hydraulic presses, engineering machinery, and ships.

At its core, the plunger pump operates through changes in hydraulic pressure. The plunger moves within the cylinder block, altering the volume of the sealed working chamber. This movement facilitates the processes of oil absorption and oil pressure generation. The pump features one-way suction and discharge valves. When the plunger is retracted, the working chamber's pressure drops, causing the outlet valve to close. As the pressure falls below the inlet pressure, the inlet valve opens, allowing liquid to enter. Conversely, when the plunger is pushed in, the working chamber's pressure increases, closing the inlet valve. Once the pressure exceeds the outlet pressure, the outlet valve opens, discharging the liquid.

The transmission shaft drives the cylinder block to rotate, with the swashplate either pulling or pushing the plunger out of the cylinder block. This motion completes the oil suction and drainage cycle. The oil within the working chamber, formed by the plunger and the cylinder hole, communicates with the pump's oil suction and discharge chambers via the oil distribution plate. The variable mechanism adjusts the swashplate's inclination, altering the pump's displacement. This is the fundamental operating principle of the ceramic plunger pump.

The ceramic piston pump's structure is not overly complex, typically divided into axial and radial piston pumps. The radial piston pump, in particular, boasts high technical sophistication and efficiency, marking it as a future mainstay in piston pump applications.

Proper maintenance of the plunger pump is crucial for extending its service life. Axial piston pumps generally utilize a rigid body rotation and end face flow distribution system. The cylinder block's end face is inlaid with a friction pair consisting of a bimetallic plate and a steel oil distribution plate. Most systems employ plane flow distribution, simplifying the maintenance process.

Understanding the ceramic plunger pump's operation, structure, and maintenance is essential for maximizing its performance and longevity. By grasping these fundamentals, users can ensure that their equipment remains in optimal condition, ready to handle the demands of high-pressure applications across various industries. Whether in hydraulic presses, engineering machinery, or ships, the ceramic plunger pump stands as a testament to the importance of precision engineering in the modern world.

Performance:

1. The strong acid and alkali resistance of zirconia ceramic shall be better than other materials.

2. Zirconia ceramics are not easy to wear, with strong durability. The hardness is close to the natural diamond and light than metals, also has the gem properties such as never wear and non - discoloring.

3. Can maintain the mechanical strength under high temperature, can be used in the condition with high temperature.

4. Good surface finish quality, could get more glossy smooth surface. Small coefficient of wear, with quite good self - lubricating function, non - magnetic, electric insulation, static - free, anti interference and radiation.

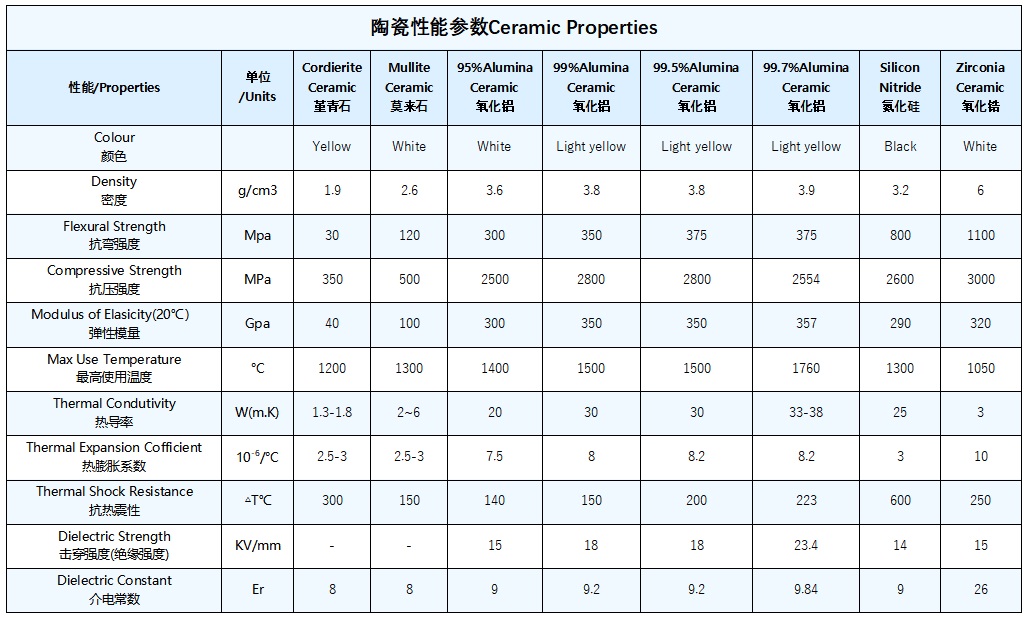

Technical Parameters

Production process

1. Grind and crush the raw materials to be slurry or powder

2. se-different method to making the slurry or powder into semi-finished products

3. Put the semi-finished products into the kiln for dewaxing and sintering;

4. After forming and sintering, Ceramic Sleeves products can also be processed by subsequent CNC precision machining according to the drawing requirements. Then Q/C test.

5. Finally package Ceramic Sleeves by bubble paper or cartons and place it on tray for delivery

Certifications

Our customers

Packaging and shipping

Transport

FAQ:

Q: Do you have the products in stock?

A: Some standard produce have in stock, such as ceramic band heater insulator; bobbin heater insulator and ceramic connector. But it needs to check according to your requirement.

Q: How do you pack the goods?

A: Our standard packaging is carton, we can customize it as per your requirement as well.

Q: How many days do you finish the sample?

A: Usually 15 business days (Including 8days for making furnaces and 7days for producing samples)

Request A Quote Today

Whether is a product enquiry or technical help, please send messager here, our team will respond within 8 hours.

Subject : Advanced Technical Ceramic Plunger Pump / Dispensing Valves Made From Zirconia

If you have any questions or need help, feel free to contact with our team.

Phone

+86 18068252612

Location

Qianluo Village, Dingshu Town, Yixing City, Jiangsu Province, China

Welcome to subscribe to our email message!

Copyright © Yixing Shengda Refractory Ceramic Co., Ltd. All Rights Reserved | Sitemap | Powered By