Ceramic products have good performance and can be made into different shapes according to different requirements of customers. Customers need to provide drawings or pictures, and we can use the production method of full processing or mold pressing to produce corresponding products. For the tolerance, roughness, parallelism and other requirements of products, we can make products according to the requirements.

Product Introduction

Porous MgO Magnesium Oxide Ceramic Spacer Ceramic Tube

Magnesium oxide (MgO) ceramic gaskets are engineered materials renowned for their exceptional performance in high-temperature and chemically corrosive environments. These gaskets are fabricated from magnesium oxide, a compound that boasts a melting point exceeding 2800 degrees Celsius, making it an ideal choice for applications where conventional materials may fail.

The unique properties of MgO ceramic gaskets include excellent thermal conductivity and electrical insulation. They are chemically inert, resistant to a wide range of acids, alkalis, and solvents, and can operate effectively under extreme pressures and temperatures. This makes them suitable for use in various industries such as petrochemical, chemical processing, power generation, aerospace, and automotive, particularly in flanges and pipe fittings where a reliable seal is critical.

MgO ceramic gaskets are also favored for their non-asbestos composition, aligning with health and environmental regulations that restrict the use of hazardous materials. They offer a long service life, reducing the need for frequent replacements and minimizing maintenance costs.

In summary, MgO ceramic gaskets are high-performance sealing solutions that provide robust, reliable service in demanding industrial applications, ensuring safety, efficiency, and compliance with stringent industry standards.

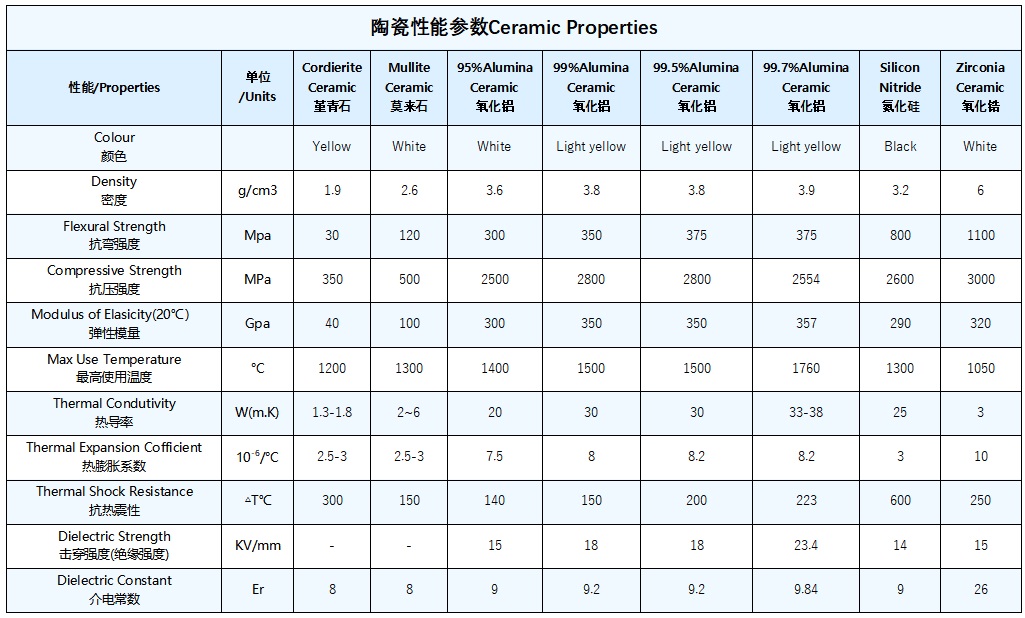

Technical Parameters

Production process

1. Grind and crush the raw materials to be slurry or powder

2. se-different method to making the slurry or powder into semi-finished products

3. Put the semi-finished products into the kiln for dewaxing and sintering;

4. After forming and sintering, Ceramic Sleeves products can also be processed by subsequent CNC precision machining according to the drawing requirements. Then Q/C test.

5. Finally package Ceramic Sleeves by bubble paper or cartons and place it on tray for delivery

Certifications

Packaging and shipping

FAQ:

Q: How can I get the after-service?

A: Any quality problem, feel free to contact us, we’ll deal with it within 3 working days.

Q:What kind of transportation mode do you have?

A: By Sea/By Train/By Air or By Express, 15-20days Against Deposit.

Q: How is your price level?

A: Factory direct sale, we have whole production line work process from platform to main parts. We have hot injection machine and dry pressing machine.

Request A Quote Today

Whether is a product enquiry or technical help, please send messager here, our team will respond within 8 hours.

Subject : Porous MgO Magnesium Oxide Ceramic Spacer Ceramic Tube

If you have any questions or need help, feel free to contact with our team.

Phone

+86 18068252612

Location

Qianluo Village, Dingshu Town, Yixing City, Jiangsu Province, China

Welcome to subscribe to our email message!

Copyright © Yixing Shengda Refractory Ceramic Co., Ltd. All Rights Reserved | Sitemap | Powered By