Shengda Ceramics can customize products according to customers' requirements.

Product Introduction

Excellent Electrical Insulation Boron Nitride Screw Bn Ceramic Bolt For Refractory

Boron nitride (BN) ceramics are compounds composed of boron and nitrogen atoms, offering a variety of unique characteristics. They are available in two main crystalline forms: hexagonal (h-BN), resembling graphite, and cubic (c-BN), similar to diamond in structure. Hexagonal BN is often referred to as "white graphite" due to its layered structure, while cubic BN is one of the hardest known materials, second only to diamond.

These ceramics exhibit high thermal conductivity, rivalling that of metals, and possess a high melting point exceeding 2300°C. They also have a low coefficient of thermal expansion, making them stable at high temperatures. Chemically inert, they resist most acids and bases, and they provide excellent electrical insulation.

Applications for boron nitride ceramics span across various industries. They are used in high-temperature environments as refractory materials, in the electronics industry for insulating semiconductor devices, and in mechanical engineering for cutting tools and abrasives. Additionally, their lightweight and high-strength properties make them suitable for aerospace components.

Manufacturing methods for boron nitride ceramics include chemical vapor deposition (CVD), hot pressing, and reaction sintering. Environmentally friendly, these materials produce no harmful by-products during production and use. As technology advances, the applications of boron nitride ceramics are expanding into nanotechnology and biomedical engineering, promising a bright future for this versatile material.

Main Features:

1. High hardness

2. High heat resistance

3. Good wear resistance

4. High electrical resistivity

5. High corrosion resistance

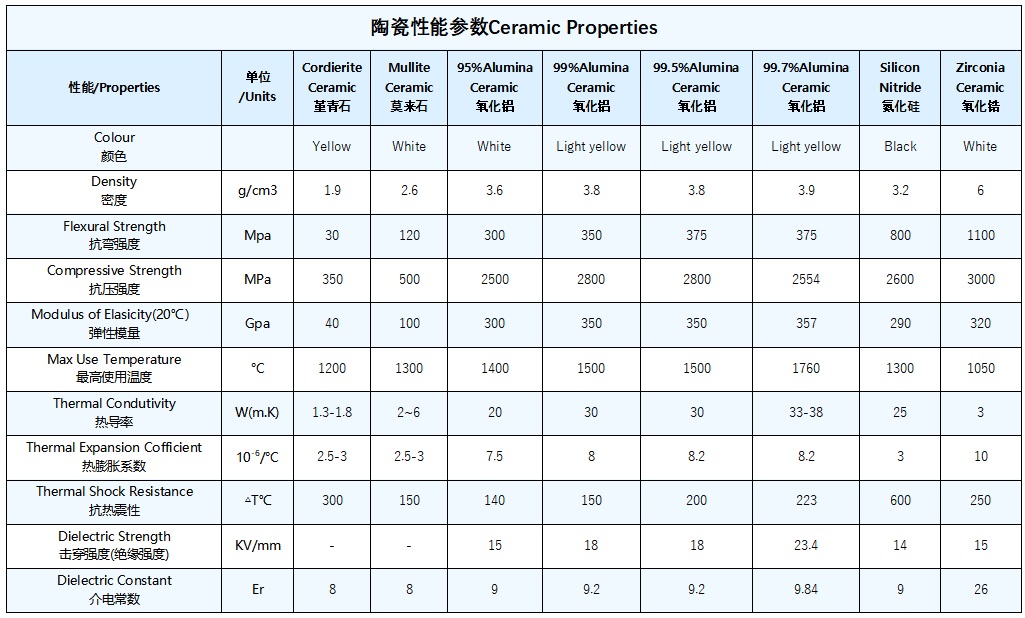

Technical Parameters

Production process

1. Grind and crush the raw materials to be slurry or powder

2. se-different method to making the slurry or powder into semi-finished products

3. Put the semi-finished products into the kiln for dewaxing and sintering;

4. After forming and sintering, Ceramic Sleeves products can also be processed by subsequent CNC precision machining according to the drawing requirements. Then Q/C test.

5. Finally package Ceramic Sleeves by bubble paper or cartons and place it on tray for delivery

Certifications

Packaging and shipping

FAQ:

Q: Are you a factory or a trading company?

A: We are a factory established in 1995 with more than 22 years of OEM and international trade experience.

Q: Do you provide customized service?

A: Yes, we have a professional team which has rich experience in industrial ceramics,so we'll try to satisfy your requirement.

Q:How long is the production cycle?

A: 10-30 days depends on your purchasing quantity.

Request A Quote Today

Whether is a product enquiry or technical help, please send messager here, our team will respond within 8 hours.

Subject : Excellent Electrical Insulation Boron Nitride Screw Bn Ceramic Bolt For Refractory

If you have any questions or need help, feel free to contact with our team.

Phone

+86 18068252612

Location

Qianluo Village, Dingshu Town, Yixing City, Jiangsu Province, China

Welcome to subscribe to our email message!

Copyright © Yixing Shengda Refractory Ceramic Co., Ltd. All Rights Reserved | Sitemap | Powered By