Shengda Ceramic provide all kinds of Al2O3 Alumina Engineering Ceramics.

Product Introduction

Customize 95 Alumina Inner Hexagonal Ceramic Shaft Sleeve For Deep Well Pump

The 95% alumina ceramic bushing designed for deep well pumps is an engineered component that offers exceptional performance in demanding environments. Made from high-purity alumina (Al2O3), this ceramic bushing is characterized by its high hardness, wear resistance, and chemical inertness, making it ideal for applications involving abrasive materials and corrosive substances.

The 95% alumina content provides the bushing with a unique combination of properties that include:

High Abrasion Resistance: The hardness of the ceramic material ensures that it can withstand the wear and tear associated with deep well pump operations.

Corrosion Resistance: Alumina ceramic is virtually unaffected by most chemicals, including acids, alkalis, and salts, which is crucial for longevity in harsh chemical environments.

Thermal Stability: With a low coefficient of thermal expansion, the bushing maintains its structural integrity under varying temperature conditions, which is essential for deep well pumps that operate in extreme heat.

Low Friction Coefficient: This property helps in reducing the energy consumption of the pump and extends the service life of the associated mechanical components.

These ceramic bushings are precision-engineered to fit snugly around the shafts of deep well pumps, providing a smooth and durable interface that minimizes friction and maximizes efficiency. They are widely recognized for their reliability and are a preferred choice in the oil and gas industry, as well as in applications involving high-pressure water pumps.

Main Features:

1. High hardness

2. High heat resistance

3. Good wear resistance

4. High electrical resistivity

5. High corrosion resistance

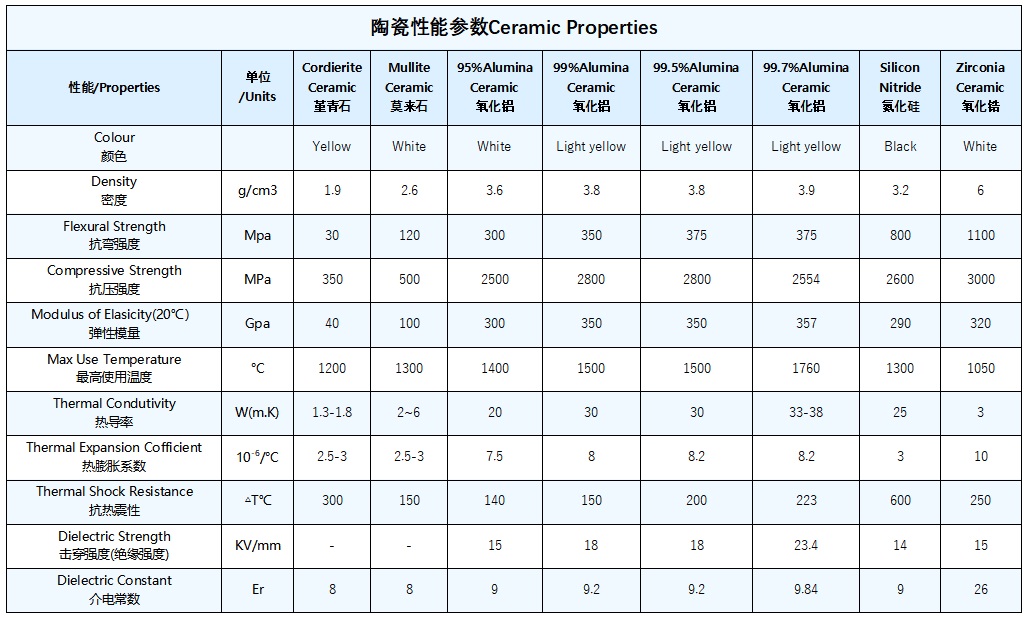

Technical Parameters

Production process

1. Grind and crush the raw materials to be slurry or powder

2. se-different method to making the slurry or powder into semi-finished products

3. Put the semi-finished products into the kiln for dewaxing and sintering;

4. After forming and sintering, Ceramic Sleeves products can also be processed by subsequent CNC precision machining according to the drawing requirements. Then Q/C test.

5. Finally package Ceramic Sleeves by bubble paper or cartons and place it on tray for delivery

Certifications

Our customers

Packaging and shipping

Transport

FAQ:

Q: Do you have the products in stock?

A: Some standard produce have in stock, such as ceramic band heater insulator; bobbin heater insulator and ceramic connector. But it needs to check according to your requirement.

Q: How do you pack the goods?

A: Our standard packaging is carton, we can customize it as per your requirement as well.

Q: How many days do you finish the sample?

A: Usually 15 business days (Including 8days for making furnaces and 7days for producing samples)

Request A Quote Today

Whether is a product enquiry or technical help, please send messager here, our team will respond within 8 hours.

Subject : Customize 95 Alumina Inner Hexagonal Ceramic Shaft Sleeve For Deep Well Pump

If you have any questions or need help, feel free to contact with our team.

Phone

+86 18068252612

Location

Qianluo Village, Dingshu Town, Yixing City, Jiangsu Province, China

Welcome to subscribe to our email message!

Copyright © Yixing Shengda Refractory Ceramic Co., Ltd. All Rights Reserved | Sitemap | Powered By