Shengda Ceramic can provide all kinds of alumina ceramic tubes according to drawings or pictures. Also can supply the mirror surface treatment to meet the sealing requirements of bearings, etc. Any dimension requirement, please contact us.

Product Introduction

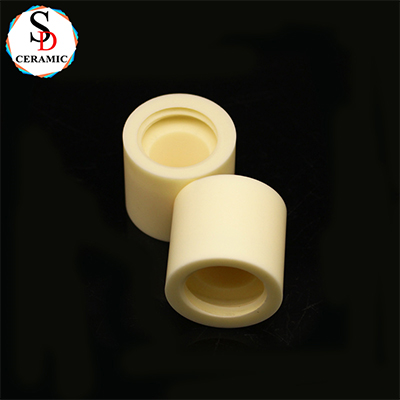

High Purity 99% Alumina Ceramic Sleeve Industrial Ceramic

Alumina ceramic sleeves, composed of 99% pure aluminum oxide, are high-performance components renowned for their exceptional mechanical and physical properties. These bushings exhibit remarkable hardness, wear resistance, and thermal stability, making them ideal for applications in various industries such as automotive, aerospace, and heavy machinery. With a high melting point and excellent electrical insulation, 99% alumina ceramic bushings are also favored for electrical and electronic applications where high-temperature resistance and dielectric strength are critical. Their chemical inertness ensures compatibility with a wide range of materials and environments, contributing to their longevity and reliability in service. Furthermore, their low coefficient of thermal expansion helps maintain dimensional stability under varying temperature conditions, a feature that is particularly beneficial in precision engineering.

Main Features:

1. High hardness

2. High heat resistance

3. Good wear resistance

4. High electrical resistivity

5. High corrosion resistance

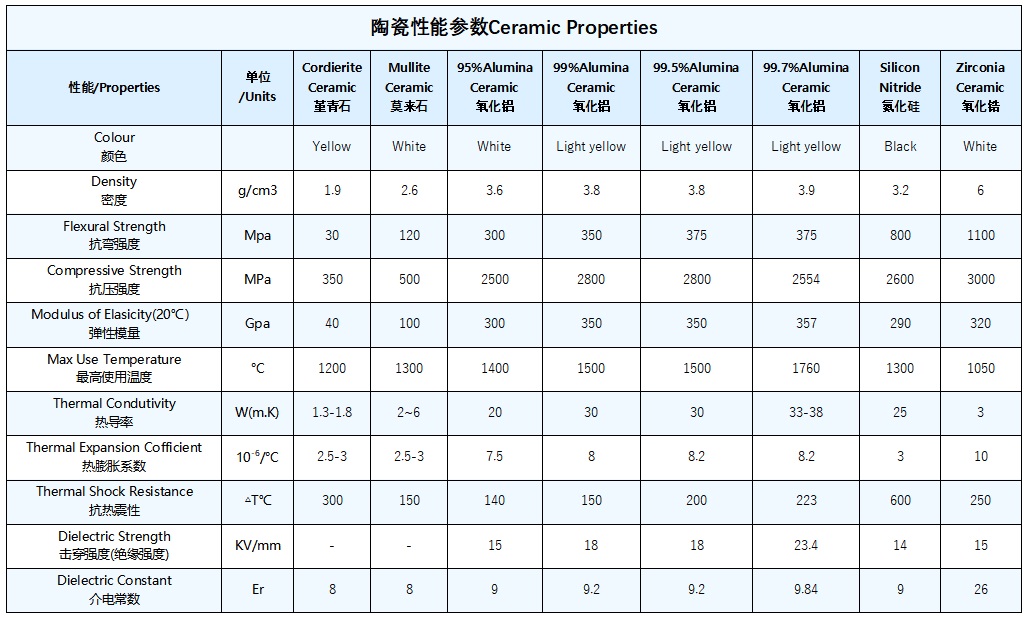

Technical Parameters

Production process

1. Grind and crush the raw materials to be slurry or powder

2. se-different method to making the slurry or powder into semi-finished products

3. Put the semi-finished products into the kiln for dewaxing and sintering;

4. After forming and sintering, Ceramic Sleeves products can also be processed by subsequent CNC precision machining according to the drawing requirements. Then Q/C test.

5. Finally package Ceramic Sleeves by bubble paper or cartons and place it on tray for delivery

Certifications

Our customers

Packaging and shipping

Transport

FAQ:

Q: Do you have the products in stock?

A: Some standard produce have in stock, such as ceramic band heater insulator; bobbin heater insulator and ceramic connector. But it needs to check according to your requirement.

Q: How do you pack the goods?

A: Our standard packaging is carton, we can customize it as per your requirement as well.

Q: How many days do you finish the sample?

A: Usually 15 business days (Including 8days for making furnaces and 7days for producing samples)

Request A Quote Today

Whether is a product enquiry or technical help, please send messager here, our team will respond within 8 hours.

Subject : High Purity 99% Alumina Ceramic Sleeve Industrial Ceramic

If you have any questions or need help, feel free to contact with our team.

Phone

+86 18068252612

Location

Qianluo Village, Dingshu Town, Yixing City, Jiangsu Province, China

Welcome to subscribe to our email message!

Copyright © Yixing Shengda Refractory Ceramic Co., Ltd. All Rights Reserved | Sitemap | Powered By